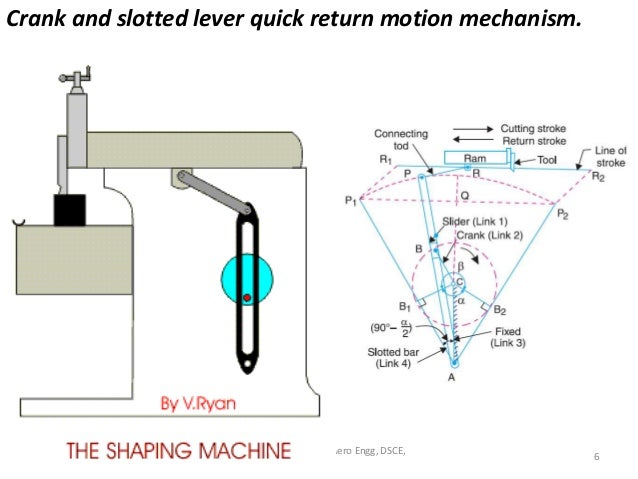

The quick return mechanism of a machine can e obtained by the following Methods: 1. Crank and slotted link mechanism. Whith worth quick return mechanism. Hydraulic shaper mechanism. PRINCIPLE OF OPERATION OF THE SHAPING MACHINE: The length of stroke and position of stroke can be changed. Single Point Tool reciprocates on the job. Job is fed across the tool. Tool is moved downward after completion of cross feed. Shaper machine is used for generating flat surfaces. Crank and Slotted Link Mechanism An electrical motor runs the driving pinion (S) at a uniform speed. This pinion makes the bull gear (M) to rotate at a uniform speed. Bull gear is a large gear fitted inside the column. A quick return mechanism such as the one seen below is used where there is a need to convert rotary motion into reciprocating motion. As the disc rotates the black slide moves forwards and backwards. Many machines have this type of mechanism and in the school workshop the best example is the shaping machine.

The shaping machines are classified as follows :

- According to the type of driving mechanism

- Crank type

- Hydraulic type

- Geared type

- According to the design of the table

- Plain shaper

- Heavy duty shaper

- Standard shaper

- Universal shaper

- According to the position and travel of ram

- Horizontal shaper

- Vertical shaper

- According to the type of cutting stroke

- Push cut shaper

- Draw cut shaper

CrankTypeShaper

Crank and slotted link mechanism of a crank type shaper converts the rotation of an electric motor into reciprocating movement of the ram. Though the lengths of both the forward and return strokes are equal, the ram travels at a faster speed during return stroke. This quick return is incorporated in almost all types of shaper.

HydraulicShaper

The ram of a hydraulic shaper is connected to a piston. Oil at high pressure is pumped to the cylinder of the hydraulic system. As the oil pushes the the piston, the ram reciprocates. Hydraulic shapers are high power machines and are used for heavy duty work.

UniversalShaper

Crank And Slotted Link Mechanism Of Shaper Machine Tool

The universal shaper has a special type of table which can be swiveled and positioned at any angle about a horizontal axis. Apart from the cross and vertical travel, the table of a universal shaper can be swiveled to any angle to machine inclined surfaces. In the process, the position of the work in the table need not be changed. These machines are utilized in precision workshops.

Slotter Machine is a resiprocating machine in which, the ram which holds the tool resiprocates in vertical direction and the cutting process is done only in the downward stroke and not in the downward stroke. This machine is similar to a shaper or planar machine.

The working principle of Slotter Machine is same as that of Shaper Machine. The only difference between a shaper machine and slotter machine is that ram of the shaper machine operates in horixontal direction and the ram of the slotter machine operates in vertical direction.

# Vertical Shaper Machine and Slotter Machine are almost similar if the construction, operation and use are concerned.

Parts of Slotter Machine

Explain Crank And Slotted Link Mechanism In Shaper Machine

1 Base or Bed:

As the name suggests, it is the base of the slotter machine. All other parts of machine are present over this base. The base is made up of cast iron which can take compressive loads by different parts of machine.

Cast iron is a very robust and rigid material. The shock absorbing capacity of cast iron is also high.

2 Column:

Column is present just above the base and is made of cast iron. It is attached to the base and box-like in shape.

This column is housing for the different driving mechanism components like gear arrangements, pulleys etc which causes the resiprocating action of ram.

This column also act as a support for the ram and worktable. Guideways are created on the top of column on which the ram can slide.

3 Guide Ways:

At the front face of column guide ways are present. It is also known as vertical guideways as it oriented in a vertical direction on the face of column.

4 Ram:

Ram main function is to resiprocate up and down when it wil get power from the driving mechanism of the machine present inside the column.

5 Cutting Tool:

This is the part of the slotter machine which cut unwanted part from the workpiece. Single point cutting tool is used as cutting tool in slotter machine. It i made up of high speed steel.

6 Carriage:

Carriage is present above the base which carry all the parts present below and above the table. It carries saddle, cross-slide, rotary table and workpiece.

7 Saddle:

The Saddle is mounted upon the guideways and can move towards or away from the column.

It can be moved either by power or manual control to supply longitudinal feed to the work.

The top face of the saddle is finished properly to provide guideways for the cross-slide. The guideways on the saddle are perpendicular to the guideways on the base.

8 Cross – Slide:

The cross-slide is mounted on the face of the column and can moved paralled to the face of the column i.e can move wither in forward or backward direction.

It can moved wither manually or by supplying power to obtain cross-feed.

9 Rotary Table:

Rotary table is a circular table which is present on top of cross-slide. This table can be rotated, so it is known as Rotary Table.

It can be rotated by rotating a worm that meshes with a worm gear connected to the underside of the table.

It this rotary table, T-slots are cut on the top face of the table so that different clamping devices can be fitted to hold the workpiece. This table enables a circular or contoured surface to be generated on the workpiece.

In some of the slotter machine, the table is graduated in degrees so that the table can be rotated for indexing or diving the periphery of a job in equal no of parts.

Drive Mechanism of Slotting Machine:-

In slotting machine, the metal is cut during the upward stroke and no metal is removed during the downward stroke. So, the time taken in downward stroke can be reduced to improve the working speed of the machine.

So, quick return mechanism is used to drive the ram of the slotting machine.

Quick return mechanism is an appratus to produce a reciprocating motion in which the time taken in return stoke is less than time taken in forward stroke.

There are three types of quick return mechanism which can be used in slotter machine :-

1) Hydraulic drive.

2) Crank and slotted link mechanism.

3) Withworth mechanism.

Crank And Slotted Link Mechanism Of Shaper Machines

Types of Slotter Machine:-

There are mainly four types of slotter machine :-

1. Puncher Slotter

2. Precision Tool Room slotter

3. General Production Slotter

4. Keyseater Slotter

1. Puncher Slotter:

Puncher slotter is very weighty machine and is operated with powerful motor. This slooter is used to remove large quantity of metals from large forging or castings.

The length of stroke of puncher slotter is also large nearly 1800 to 2000 mm.

The puncher slotter ram is usully driven by a spiral pinion meshing with rack teeth cut on the underside of the ram. In this slotter, the feed is also cut by electrical gears.

2. Precision Tool Room Slotter:

Precision Tool Room Slotter is lighter machine and is operated at high speed. This slotter is made for very precise machining.

This machine is designed to take very light cuts and give very accurate finishing. As this machine uses special jigs, it can handle a number of works on a production basis.

This machine is also good for general purpose work. This machine genrally uses Whitworth quick return mechanism for reciprocating action of ram.

3. General Production Slotter:

Production Slotter is mainly used for general production work. Slotted disc with connecting rod is used for resiprocating action of ram. Flywheel is used in this slotter to prevent stroke at the end of the stroke.

4. Keyseater Slotter:

Keyseater slotter also identified as keyseating machines are specific type of slotter designed to cut keyways. Keyseater is similar to vertical shapers, the difference is that cutting tool on a keyseater enters the workpiece as of bottom and cuts on down-stroke, as the tool on a shaper enter the workpiece as of the top and cuts downward.

Slotter Machine Operations:

There are mainly four types of operations done using Slotter Machine :-

1. Flat surface machining.

2. Machining Irregular surface

3. Cylindrical surface machining

4. Machining slots, keyways and grooves.

1. Flat Surface Machining:

Flat surfaces can be easily generated using slotter machine both internally as well as externally.

At first, the workpiece to be machined is supported on parallel strips so that the tool will have clearance with the table when it is at the extreme downward position of the stroke.

The work is then clamped properly on the table and the position and length of the table are adjusted.

A clearance of nearly 20 to 25 mm are provided before the beginning of the cutting stroke, so that the feed movement can take place during idle stroke.

The table is clamped properly to prevent any longitudinal or rotary moevement. Work is done using a roughing and a finishing tool.

If internal surface has to be machined, a hole is drilled into the workpiece through which the slotter tool can pass at the time of first cutting stroke.

In case a second surface parallel to the first machined surface has to be machined, it can be done without changing the setting only by rotating the table through 180 degrees.

If a surface perpendicular to the first surface has to be machined, it can be done by rotating the table by 90 degrees and adjusting the saddle and cross-slide.

2. Machining irregular surface:

For machining irregular surface, the workpiece is clamped on the table and necessary adjustments of the tool and the machine are made.

Irregular surface can be machined by combining different feed movements like cross, longitudinal and rotary feed moevements. Any contoured surface can be machined using these three feed movements.

3. Cylindrical surface machining:

Slotter Machine can be used easily machining cylindrical surfaces. It can be used to machine internal as well as external surface of a cylinder.

The tool is set radially on the work and necessary adjustments of tool, saddle, table,cross-slides are made. The saddle is clamped in its position.

After all the adjustements, the machine is started and while mahining feed is provided using rotary table feed screw which rotates the table through a small arc after each cutting stroke.

4. Machining slots, keyways and grooves:

For machining slots, keyways and grooves special type of slotter is used known as keyseater slotter which we discussed earlier. Internal as well as external grooves are cut very easily using this machine.

A slotty is specially made for cutting internal grooves which are very difficult to produce in any other machine.

A slotter is specially made for cutting internal grooves which are very difficult to produce in any other machine.

Gear teeth can also be machined in a slotter externally as well as internally by cutting equally spaced grooves on the periphery of the work.The division of periphery of the workpiece is done by graduation of the rotary table.